In our last blog, we discussed how building modular mezzanines for seismic-heavy areas is an essential and complex step to ensuring employees and materials are safe when an earthquake strikes. Recently, we got to put these tools to the test by building a modular mezzanine for Universal Studios in California that would lie directly on the San Andreas Fault Line.

Size Matters

The larger the structure, the more important its seismic safety becomes. The modular mezzanine in questions would occupy Universal’s Thunderdome Warehouse, so named for one of their vintage rides. This warehouse required a mezzanine that was 50 feet by 58 feet with a top of deck platform that would reach 14 feet high. In order to keep such a large structure seismic-resistant, we combined Type 1 beam to column connections along with other seismic design considerations. This included boxing around existing seismically designed building columns to ensure maximum safety.

Type 1 Connections

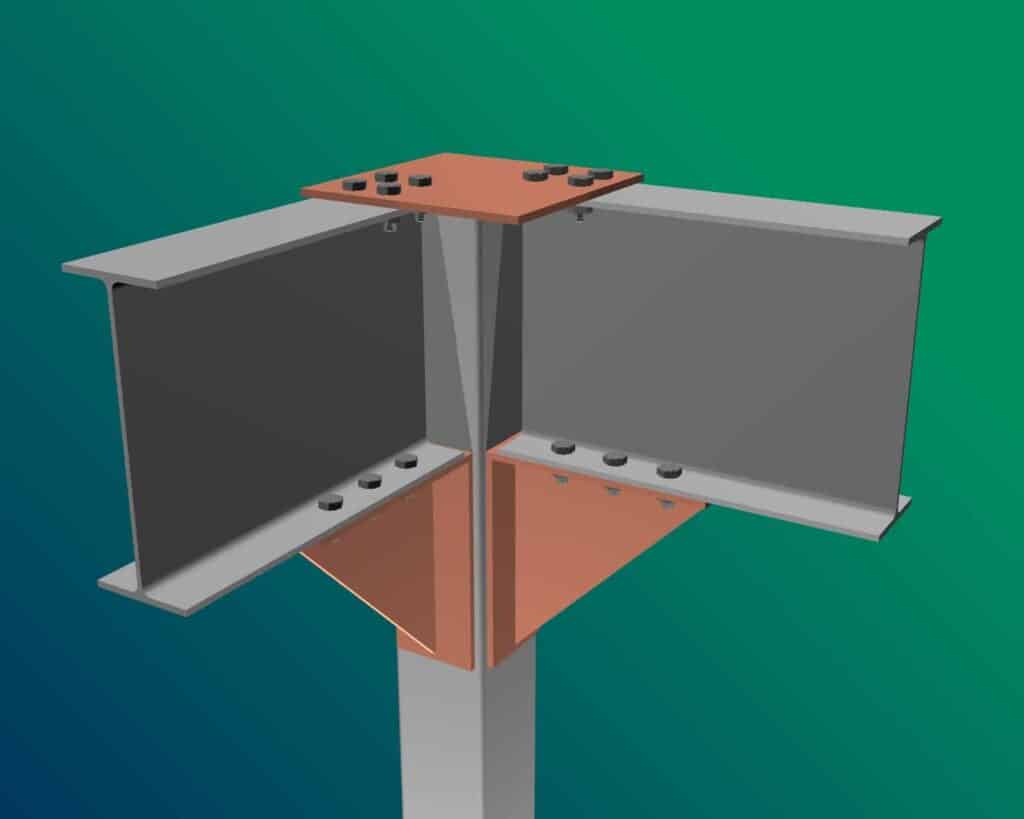

Modular mezzanines are used to organize and store important materials for warehouses around the country. Therefore, the amount of usable space is essential. To maximize the amount of available space while also ensuring safety during an earthquake, we used a full moment connection recommended by the American Institute of Steel Construction (AISC).

This “Type-1” rigid frame connection (pictured above) is truly unique to Porta-King because its full moment connection does not need knee braces or cross braces to stabilize the modular mezzanine. Other pre-engineered mezzanine designs use substantial knee braces or cross braces, which greatly reduce the usable space underneath the structure. Without them, the Thunderdome Warehouse is able to safely store and move more materials from their mezzanine.

Boxing Considerations

Our giant mezzanine was built around many existing 18 inch by 18 inch building columns that supported the ceiling 120 feet from the ground. If these were to sway or move during an earthquake, we wouldn’t want the mezzanine’s platforms or pillars to be affected by the stress. Therefore, we used boxing at every pillar to ensure both the warehouse’s and the mezzanine’s structural components remained intact.