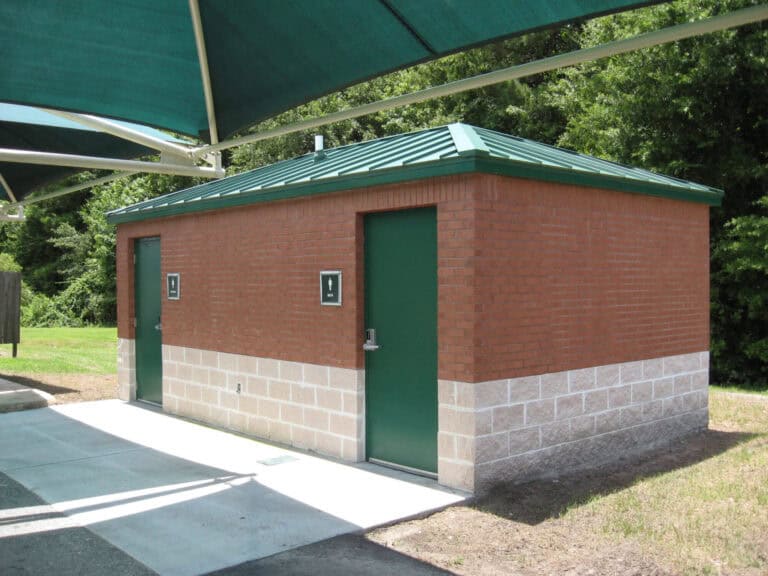

Custom Preassembled Building Designs Meet Your Company’s Unique Needs

Application, personnel, and location can all affect the final designs for your exterior building. Outdoor preassembled buildings can be modified according to your specifications for:

- Size and layout to accommodate a specific type of equipment or number of employees who will work in the building at one time.

- Functionality, which is determined by the number, location, and type of doors and windows as well as duct systems, heating and cooling, and electrical options.

- Safety ratings, to ensure your personnel and equipment are kept safe.

- Exterior style to match surrounding buildings (i.e. Porta-King’s Faux Stone Finish)

You can browse these design options before speaking to a Porta-King representative to better understand how they fit your needs.

Low Maintenance = High Performance

All Porta-King high quality products are built to stand the test of time, but this standard is especially important when designing and building portable buildings. Unlike in-plant buildings, these exterior buildings are solely responsible for protecting contents from outside forces.

Our bullet resistant walls and glazing are specially designed panels that protect your building from direct attack by providing different levels of NIJ and UL 752 ratings. For more information on these specializations, contact a Porta-King representative today.

Preassembled Building Video Gallery

In this video we walk you through a 12’ x 26’ Durasteel PC press box with mezzanine structure, viewing deck and overhead canopy at Delbarton High School in Morris Township, New Jersey.

Permanent Solutions with Sustainable Architecture

Preassembled structures are a long-term solution for practically any application. Of course, the term “portable buildings” implies that these structures can be easily moved as a unit. Therefore, every building you invest in can be repurposed in the future if your needs change.

In addition to your building’s reusability, portable buildings are prefabricated in a factory’s controlled environment and then shipped to your site for immediate installation. This workflow reduces construction waste and downtime at your facility, offering a green alternative to traditional construction.

Frequently Asked Questions

What are the construction options for preassembled buildings?

When considering a preassembled building, it’s essential to understand the available construction options to ensure that you choose the best solution for your specific needs. Porta-King offers four primary construction options for the base design of your preassembled building: steel (Durasteel), steel (Durasteel ES), anodized aluminum with FRP finished surface (Duraluminum), and FRP faced wall panels mechanically fastened to an anodized aluminum framework (Duraluminum).

Durasteel buildings feature an epoxy-painted steel surface, providing durability and versatility for a wide range of applications. The Durasteel ES variant is a modified version that reduces the number of structural steel tubes by bending the edges of the wall panels and welding them together. This budget-friendly design is ideal for smaller footprint structures that require protection from the elements, such as shelters for pumps, generators, and other equipment.

Duraluminum buildings utilize an anodized aluminum framework with FRP faced wall panels, offering a corrosion-resistant and lightweight alternative to steel. These panels are mechanically fastened together at Porta-King’s factory prior to shipping, ensuring a quick and efficient on-site installation.

By understanding the unique characteristics and advantages of each construction option, you can make an informed decision when selecting a preassembled building that best suits your specific application, budget, and environmental considerations.

Is steel or aluminum a better option for a Parking Booth?

When deciding between steel and aluminum for your Parking Booth, there are several factors to consider:

1. Geographical location: If your booth will be located in coastal areas where salt can affect painted steel surfaces over time, aluminum may be a more suitable choice for its inherent corrosion resistance.

2. Architectural features: If you require a booth with enhanced architectural features or custom design elements, the welded construction of Porta-King’s Durasteel system may be the preferred option.

3. Energy code compliance: In cases where energy code compliance is a requirement, Durasteel buildings can be easily modified to increase insulation values, making them a better choice for meeting these standards.

4. Ballistic rating: If your Parking Booth requires ballistic-rated construction, it’s important to note that Porta-King’s Duraluminum models have limitations on the level of ballistic resistance they can provide compared to steel options.

5. Budget considerations: Duraluminum buildings tend to be a more budget-friendly option compared to Durasteel, which may influence your decision if cost is a primary concern.

By carefully evaluating your specific needs and priorities, you can determine whether steel or aluminum is the best choice for your Parking Booth. Consulting with a knowledgeable provider like Porta-King can help you weigh the pros and cons of each option and make an informed decision based on your unique requirements.

How does Porta-King prevent rust on their steel booths?

Porta-King takes a comprehensive approach to prevent rust on their steel booths, ensuring long-lasting durability and appearance. The process begins with a thorough cleaning of all steel surfaces using an environmentally friendly paint wash. This step removes any dirt or impurities that could potentially affect the adhesion of the paint.

After the cleaning process, the booth is moved into Porta-King’s spacious 2,500 square foot heated paint booth, where it is allowed to dry completely before painting begins. This controlled environment ensures optimal conditions for the application of the protective coatings.

Once the booth is dry, a high-solid, rust-inhibitive primer is applied to the steel surfaces. This primer acts as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal.

Finally, a minimum of two coats of a two-part polyurethane paint is applied over the primer. This high-quality, durable paint system provides an additional layer of protection against rust and weathering, while also enhancing the booth’s aesthetic appeal.

By following this meticulous process, Porta-King ensures that their steel booths are well-protected against rust and corrosion, providing their customers with a long-lasting and reliable solution for their parking and security needs.

Does Porta-King offer standard models for their preassembled buildings?

While Porta-King identifies each of their preassembled buildings with a model number, they do not offer truly “standard” models. These model numbers are used to denote the type of construction (steel or aluminum) and the size of the building, but each structure is ultimately built to order, tailored to the specific needs and requirements of the customer.

For steel buildings, the model numbers represent the dimensions in feet, while aluminum building model numbers indicate the dimensions in inches. This naming convention allows for easy identification and communication of the building’s basic specifications.

However, the customizable nature of Porta-King’s preassembled buildings means that each project is unique, with options for custom layouts, finishes, and features to suit the client’s specific application. This flexibility ensures that customers receive a building that is ideally suited to their needs, rather than being limited to a set of predetermined standard models.

By working closely with Porta-King’s experienced team, customers can design and build a preassembled structure that meets their exact specifications, while still benefiting from the efficiency and quality control of a factory-built solution.

How are Porta-King’s preassembled buildings offloaded at the job site?

Porta-King designs their preassembled buildings with ease of offloading and installation in mind. For most buildings, offloading can be accomplished using a standard forklift. Each booth is shipped with skid gear attached to the base frame, allowing for easy access and maneuverability using a forklift’s tines.

In cases where a forklift is not suitable or available, Porta-King can provide alternative offloading solutions. For larger booths or those with unique installation requirements, lifting rings can be installed on the roof of the building. These rings allow for the use of cranes or other lifting equipment to safely and efficiently offload the building.

Additionally, Porta-King can design and provide custom rigging devices to address any specific challenges or constraints at the job site. This flexibility ensures that the offloading process is smooth and efficient, regardless of the site conditions or the size of the building.

By working closely with Porta-King’s team and communicating any unique requirements or limitations early in the process, customers can ensure that the offloading and installation of their preassembled building is well-coordinated and hassle-free.

How are Porta-King’s preassembled buildings secured to the ground?

Porta-King’s preassembled buildings are designed to be securely anchored to the ground, ensuring stability and safety for long-term use. The method of anchoring depends on the specific type of building and the site conditions.

For both Durasteel and Duraluminum buildings, Porta-King supplies anchor tabs for mounting the base frame to a concrete pad. In the case of Durasteel buildings, these anchor tabs are welded to the base frame at Porta-King’s factory, ensuring a strong and secure connection.

On the other hand, Duraluminum buildings are shipped with loose anchor tabs, which are installed on-site to both the building frame and the concrete pad. This approach allows for greater flexibility in the positioning and leveling of the building during installation.

In situations where the preassembled building will be placed on an elevated steel platform instead of a concrete pad, properly sized bolts are used to secure the base frame to the platform. This anchoring method ensures that the building remains stable and secure, even when elevated above ground level.

Regardless of the specific anchoring method used, Porta-King’s preassembled buildings are designed to withstand the forces of wind, weather, and daily use, providing a reliable and long-lasting solution for a wide range of applications. By working with Porta-King’s experienced team, customers can ensure that their building is properly secured to the ground, providing a safe and stable structure for years to come.